Year after year, Texas ranks among the top three states for non-fuel mining costs. Almost 90% of the state’s industrial reserves are derived from the production of cement, crushed stone, industrial sand, building stone, and gravel. Building material use is concentrated in 25 urban areas across the state. Favorable geological and economic conditions give the potential for identifying and developing new sites for the industrial mining of mineral raw materials. Learn more about the state’s mining industry at houstoname.

Industrial giant

Houston, San Antonio, Dallas, and Austin are the four most populated cities in the state, accounting for the majority of industrial mineral consumption. Texas produces more crushed stone than any other state, with over 200 quarries. Sand and gravel mining are also prevalent.

The overall cost of industrial mining in Texas from 2000 to 2015 was nearly $50 billion. Additional value was provided by imported materials that are cleaned or recycled for use in the Texas industry. Locally produced industrial rocks and minerals are commonly used in the construction industry, therefore their annual production statistics reflect the state’s economic viability.

Access to land is a critical issue in the development of industrial mineral resources in Texas since more than 95% of land is owned by private individuals. This condition presents both opportunities and obstacles to accessing natural resources. Cheap fossils in coastal markets contribute to massive ocean shipping of international raw materials, whereas regional land sources require much more expensive transportation via trucks or railroads. Similarly, imported industrial minerals may be subject to tariffs.

Almost every county in Texas produces industrial rocks and minerals, which are commonly used in local transportation, construction, and other industrial activities. Industrial mining creates jobs, and a high concentration of mineral deposits generates special products for regional distribution.

As Texas’ population keeps growing, industrial mining in the state continues to fulfill the demands of residential, commercial, and industrial consumers. Additionally, rising sea levels necessitate infrastructure modifications. In turn, this new infrastructure requires a significant quantity of construction materials and mineral resources.

Geological foundation of Texas industrial minerals

All mineral resources are the result of geological processes that have altered certain parts of the Earth’s crust over billions of years. Tectonic plate collisions developed a massive belt, the base of which served as the foundation for most of Texas. Even though the state’s area is covered with young strata, local outcrops of these metamorphic rocks and granites have long existed in Texas’s central and western regions. These igneous and metamorphic rocks produce a wide range of building and chemical materials, including building stone and talc.

During the Paleozoic era, North America collided with Southern America, resulting in tectonic movements that formed the supercontinent Pangaea. Pangaea existed throughout the Carboniferous and Early Jurassic Periods. These occurrences, along with geological outcrops in Central Texas, resulted in large oil basins. Shallow waters evaporated, creating gypsum and salt-bearing strata that became the primary potash deposits.

During the Cretaceous period, shallow shelf areas formed vast carbonate strata that formed the Edwards Plateau and other surface belts required for the manufacture of crushed stone, cement, and lime in Texas.

The Cenozoic strata of the coastal plain and the non-consolidated alluvial deposits of Texas’ main river systems generated industrial sand and gravel. They also became the source of much of the common clay used in the manufacture of bricks and pottery.

Overall, Texas’ 1.5 billion-year geological history has endowed the region with a diverse range of industrial rocks and mineral resources that are significantly relied on by the population for everyday needs.

Texas construction materials

As previously stated, crushed stone, gravel, and sand dominate industrial mining in Texas, and the construction industry consumes huge quantities of these materials. In 2015, the state generated more crushed stone than any other in the United States.

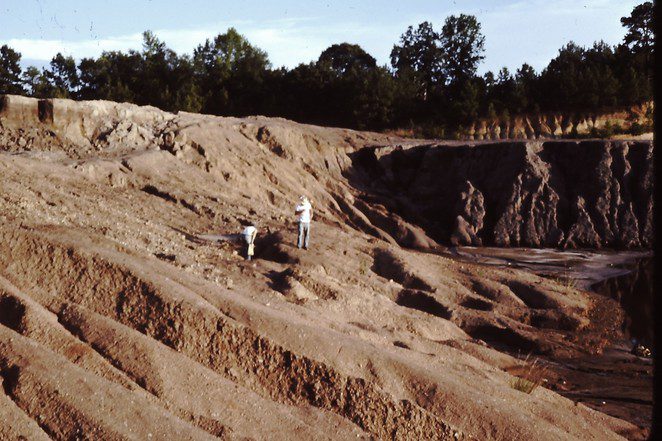

Many industrial rocks and minerals are relatively common earth resources, therefore low-cost mining processes are typically necessary for economic viability. As a result, industrial mining sites are typically located near mineral-consuming areas. Their positions are also determined by the proximity of fossils to the Earth’s surface and the availability of a transportation network for delivering the products to regional, national, and global markets.

Furthermore, rotary kilns are used to heat limestone and clay to produce cement. Due to its direct and regional application in the construction industry, cement production is a leading indicator of the strength of the local and regional economy.

Gypsum is also utilized in the manufacture of cement and in dry building mixtures. Numerous products are made from various types of clay, with ordinary clay being consumed in large quantities for the manufacturing of bricks and tiles. Texas also provides many geological varieties of building stone, which are usually used for monuments and building exteriors. In addition, industrial sand is widely used in the state.

Texas chemical minerals

Many industrial minerals are employed in the chemical industry, both primarily for industrial purposes and as sources of valuable elements.

The majority of Texas salt is manufactured to provide chlorine for the creation of hydrochloric acid, a chemical used in manufacturing. Lime is mostly used for water purification, papermaking, and sugar refining. Another essential industrial chemical is sulfur, which is mostly required for the creation of sulfuric acid, which is used in chemical fertilizers. Sulfur is manufactured at over 60 refineries using acidic crude oil and natural gas.

Special clays, zeolites, helium, sodium sulfate, and talc are also produced in limited quantities in Texas. Although the majority of clay produced in Texas is used to make bricks and other building materials, certain operations generate unique clays for drilling fluids, vegetable oil purification, the rubber and paper industries, ceramics, and other applications.

Zeolites are in high demand due to their ion exchange capacity, which is utilized in water treatment and other purification processes. There are additional clay and zeolite strata in the region that can be exploited if demand rises and economic conditions improve. Talc is commonly used as a filler in ceramics, paper, plastic, and rubber.